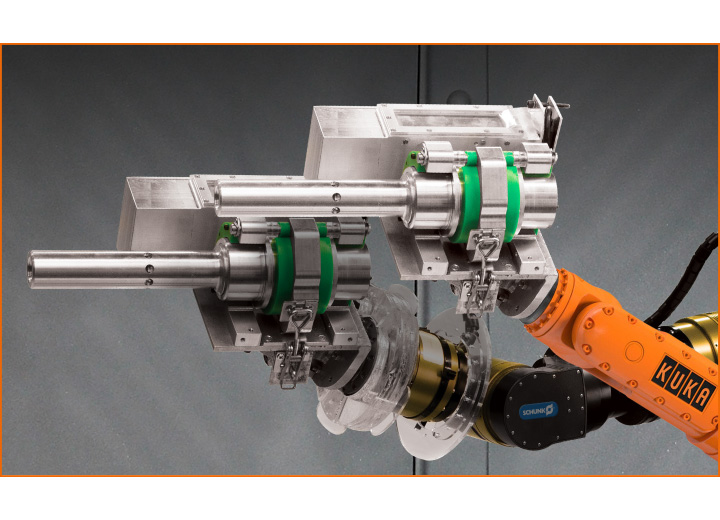

Robotic Sanding System

Efficiency

Blastman is more efficient than any traditional manual sanding system:

Higher pressure up to 10 bars, corrosive, high kinetic energy

nipples with big diameter up to 19mm

Vibrated nipple movement

Higher accuracy

Non-stop working

Safety

Manual abrasive blasting is an extremely hard, unhealthy and dangerous operation:

The operator is exposed to noise, dust and physical strain

When working with large items, the protective ladders and garments are needed

Accidents and work accidents

Frequently it may cause the delays in production.

Cleaning with automatic sanding Blastman:

In manual operation, there is a cabinet which is designed ergonomically for operator, with air conditioner and sound isolated

Automatic cleaning service robot may be monitored from a control room out of sanding chamber, and it follows predefined way

Quality

The nozzle distance and angle are continuously controlled to guarantee the required quality.

Removes the risk of human error during automatic explosion.

Short Time

Higher efficiency

Low workmanship costs

Low operating costs (energy saving)

Low maintenance cost